STREAMLINE OPERATIONS WITH OIL COOLER MAINTENANCE

Fully equipped workshops allow Coxons Group to provide the most time and cost efficient solutions for any industrial oil cooler needs. Supply, service, repair, internal and external cleaning, flushing and pressure testing are all executed on site in our market leading workshops. As an authorised Mesabi Service Centre, our capabilities extend to overhaul and supply of the full range of Mesabi Oil Coolers.

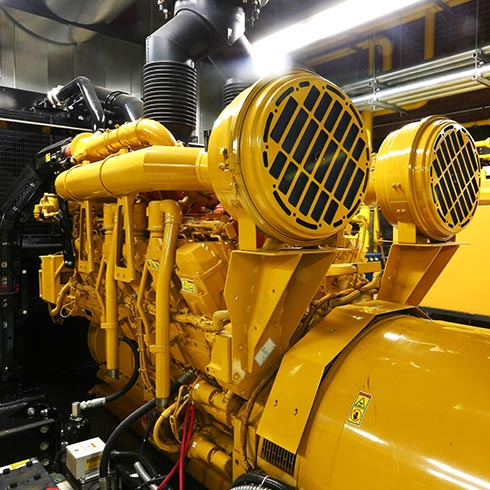

A range of Oil Coolers for underground and mining applications, with recore and replacement supplies available for Oil Cooler failures.

HEAT EXCHANGE ESSENTIALS

Oil Coolers provide the critical stage of cooling your equipments oil. Removing excess heat by continuously passing through a heat exchanger, in turn being cooled by water or air. Failure of an Oil Cooler can lead to failure of the engine, or cooling components.

Avoid contamination of the cooling system from a failing Oil Cooler, by scheduling regular servicing and pressure testing to ensure peak performance.

- A major heat exchanger for your equipment.

- Removes excess heat from your cooling system.

- Oil Cooler failure can result in catastrophic engine failure.

- Regular servicing and pressure testing of Oil Coolers is imperative.

Product Alerts

Get the latest product availability alerts

Oil Cooler FAQs

Through MineCool, we stock an extensive range of quality oil coolers to suit various mobile heavy mining equipment applications, including:

- Hydraulic excavator oil coolers

- Steering oil coolers

- Brake oil coolers

- Transmission oil coolers

- Compressor oil cooler components.

Yes, Coxons provides both repair and replacement options for oil coolers used in mobile heavy mining equipment. We offer planned maintenance services and urgent repairs in emergencies.

Yes, Coxons specialises in overhauling oil coolers for heavy mobile mining equipment. Our fully equipped workshops in Singleton, Rockhampton, Mackay and Perth can handle your complete service including supply, repairs, internal and external cleaning, flushing, and pressure testing.